|

Matchlock Musket, Suhl appr. 1630

Replica of a matchlock musket built according to an original from the art collections of the castle of Coburg. Inv. IV. D. 148. Original produced in Suhl, ca. 1630 Replica of a matchlock musket built according to an original from the art collections of the castle of Coburg. Inv. IV. D. 148. Original produced in Suhl, ca. 1630

Total length: 142 cm

Barrel length: 102,5 cm

Calibre (Bore): 19,7 mm (12 bullets/pound)

Weight: 4600 gramms

Barrel with soldered bead and dovetail slided in notch. Octagonal outer contours towards the powder chamber, after the first third transitioning via 6 half-radially cannelures into a round cross section. Decoratively shaped ring-section at the nozzle. Three original master and proof marks at the end of the powder chamber were replaced by Armin Konigs master marks. Chiseled year date without relation to the originals date of manufacture. Blackened and oiled beech stock with metal butt plate. Two ramrod holding bands and nose cap. Wooden ramrod with brass soldered metal tip. Matchlock with rectangular lockplate, 2-screw attachment.

The unwieldyness of early matchlock muskets necessarily caused military specialits and gunmakers to think about lighter contruction patterns. Already at the beginning of the Thirty Years War in 1618 the extremely heavy and burdensome devicies, as they are to be seen at the copper engravings of Jacob de Gheyn from 1607, with a weight of about 7,5 kg and more and a bore of 8 balls to the pound (appr. 21,6 mm) were outdated.

The lightening of the musket was often claimed to have been invented by Gustavus Adolphus himself. Gustavus however adopted most of his military innovations from Holland, where the conflict between the the United Dutch Provinces and the Spanish Netherlands was already lasting since 1568 and where Prince Maurits of Orange, stattholder of the Dutch Provinces, together with his cousin Johann, Count of Nassau-Siegen and Johann's brother, Willem Lodewijk of Nassau, had reformed, or in fact revolutionized the whole theory of warefare of Early Modern History. Already in 1596 Johann of Nassau wrote: "Musqueteers not necessarily need to carry those exceedingly havy muskets, thus in state of distress, and when forced to quick retreat, they can easier move foreward, and in a hurry also can shoot without using a fork [...]". In February 1599 the dutch army regulations limited the weight of the musket to about 6,5 kg, which was still fairly heavy and requiret the use of a musket rest or forquette.

During the first quarter of the 17th century large bulks of muskets were manufactured in the german towns of Suhl and Essen, in the dutch cities of Amsterdam, Utrecht, Dortrecht and ’s-Gravenhagen (the Hague). Lower quantities of muskets, but especially the lighter calivers, were built in the german cities of Nurnberg and Augsburg. Until the middle of the twenties of the 17th century also Sweden imported most of its demand on firearms from Germany and the Netherlands. From about 1627, unter the direction of dutch military enterprisers like Louis de Geer and Willem de Besche, increasing production facilities were tranfered to Sweden. While the major part of more complicated wheellock weapons still had to be imported, the simplier matchlock muskets could easily be manufacured in the country. As an example, the swedish city of Jönköping evolved as a leading swedish center of production and and even more of proofing of firearms (proofmark is a crowned ring).

Already in the year 1624 Gustavus Adolphus per decret had ordered a new and lighter pattern for matchlock muskets. However these muskets, until about 1630 manufactured in Sweden, with a directed barrel length of 115 to 118 cm (the lenght was set at about 3 feet 10 inches, with some tolerance) and a total length of about 156 cm still were rather cumbersome, while the comparable long barrel only insignificantly contributed to an increased shooting performance.

From about 1630 a new musket type evolved from the thuringian city of Suhl, the german leading center of firearms manufacturing, with further improved quality and further reduced weight. This was achieved by again shortening the barrel and reducing the barrel-thickness. This new musket generation had an average lenght of about 140 cm with a barrel lenght of 102 cm and a total weight between 4,5 and 4,7 kg. The smooth bore of the barrel was 10 balls to the pound (appr. 19,7 mm) shooting a rolling bullet of 12 to the pound (18,5-18,8 mm)*.

* please note, that 17. centuries Germany gunmakers were using several different weights. For calculating gun bores, german gunsmiths mostly used the Nurnberg Pound (509,96 gramms), which corresponded to a Saxon Heavy Pound, the Nurnberg Pound Silver Weight (477,2 Gramm), which corresponded to a Hamburg and Swedish Pound and the Anglo-Saxon Pound (453 Gramms), which was increasingly adopted by Suhl, dutch and swedish gunsmakers from beginning of the 1630s.

Already at this time there was an ongoing tendency to further lighten the calibre of muskets. From appr. 1630 both warfaring parties tented to use a musket calibre of appr. 17,8 bis 18,3 mm (14 to the pound), shooting bullets of 16 to the pound (ca. 17,0-17,5 mm, so called „zweilöthige Kugeln“ = or "one ounce balls"). From about 1634 a common musket bore (even with Suhl models) was about 17,5 mm (16 to the pound), shooting a rolling bullet of 16,8 mm (18 bullets per pound of 510 gramms). This kind of bullet can commonly be found on battle fields of the Thirty Years war from 1632 on. In parallel to this tendency the larger bores still were kept in use, especially by the swedish manufacturers, and even the dutch guidelines for proofing musket barrels in 1639 still declared a musket bore of 10 to the pound (appr. 19,7 mm) as mandatory.

Because of this still fairly large calibres even these lightened muskets still developed a ferocious recoil. They still were shot by using a musket rest, called forquette (fork). On the 6th of May 1632 the Rothenburg chronicler Sebastian Dehner however noted, that a company of swedish infantry had arrives, equipped with the new light muskets not using forquettes.

The featured musket on this page represents an exact copy of the new light musket model, built in Suhl during the years 1630 to 1634 (the year, when Suhl was destroid by croat cavallery units unter general Goan Ludovico von Isolano). Until then this model already had developed into the standard model of the swedish-protestant army and quickly was adopted by other manufacturing centers throughout Europe.

The powder chamber area of the original's barrel with pancover and fence removed. The two lower marks are that of the barrelmaker and the firearm merchant. Obove is the proofmark of Suhl.

Same detail of the reproduction. The original Suhl proofmarks replaced by master-marks of Armin Koenig. The thread of the barrel screw, exceeding the surface of the breechplug tail by several turns, looks a little bit unprecise. This however is a typical feature with most Suhl matchlock muskets. Manufacturing of threads was a complicated process in the 17th century. As it was almost impossible to avoid lenght tolerences, the screw was designed to be a little bit longer in order to make shure, that all threads of the screw would pass the threaded hole. In addidition the wood of the stock was undergoing a considerable shrinking process throughout the centuries, so by stepwise readjustment of the screw this was passing more and more through the the outer surface.

Suhl manufacturing mark of the original

Muzzle detail of the reproduction. The rim of the muzzle is shaped with a rounded edge and a diametrical cannelure, a qualitiy feature seldomly to be seen with military muskets of the early 17th century. This typical Suhl feature testifies for a high manufacturing standard. The ramrod tip in form and finish exactly complies to the original. The copper-soldered metal cap features an inside thread for fixing of a cleaning jag, bullet puller or worm. The sharply edged front end prevents the ramrod to bypass the wad, when ramming it down the barrel.

This detail (reproduction) shows the buttplate of the musket. To increase the speed of reloading, many musketeers avoided the time consuming wadding of the musket ball by using the ramrod. Instead the musketieer, after having filled the powder charge into the muzzle, dropped a bullet out of his mouth into the barrel, thus getting the powder more settled. By quickly tipping the butt onto the ground, the charge was additionally compressed and the musketeer was ready to fire. This method was faster as the normal loading procedures, but had some significant disadvantages. As musket balls were shot with a comparable large windage between the inner diameter of the barrel and the diameter of the ball, it frequently happened, that when the musketeers had to shoot downhill, the bullets starting rolling out of the barrel because of the missing wad.

Lock mechanism of the Suhl Original from inside

Reproduction lockmechanism. The inner mechanics are rather simple. Good and easy functioning however depends on many parameters: exact reproduction of measurements, angles and distance relations of pivots and levers.

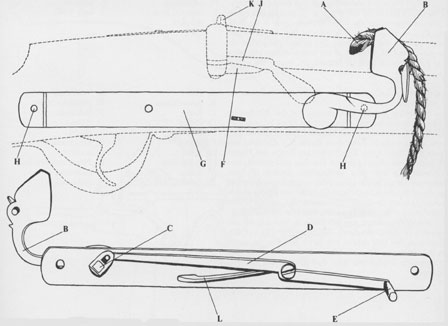

Scematics of a matchlock mechanism:

|

A Slow Match

B Serpentine or cock

C Tumbler

D Sear

E Sear lever

F Flash pan

|

G Lockplate

H Lockscrews

J Pan cover

K Flashguard or fence

L Sear spring

|

The author firing his model 1632 Suhl matchlock musket built by Armin Koenig.

In most cases, especially when using heavier muskets, the musketier was using a musket-rest or so called „forquette“. The slowmatch was lighted at both ends, so when one end was extinguished by the (as one can see, not insignificant) pan-flash, she shooter could light it again from the other end. The recoil of such a weapon of 10 bore is tremendous, especially when using a powder charge equivalant to half the weight of the bullet, as recommended in contemporary instruction manuals (not recommented to to be immitated with modern blackpowders). Wallhausen therefore, and not without reason, wrote in his „Kriegskunst zu Fuß“ in 1615: „[...] you should press your musket tightly towards your right chest, and not towards your arm, cause a musket, that pushes very hard, can easily dislocate your arm from your shoulder, or at least, when shooting six or eight times, can treat you such, that you wont be able to use your arm the following day [...]“.

Back to Firearms

|

|

|