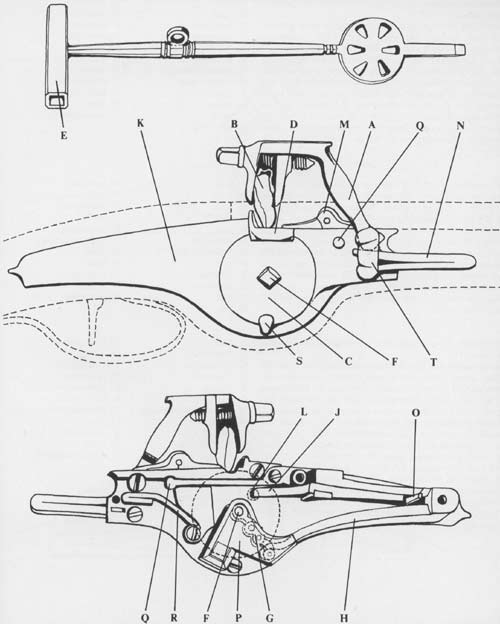

Wheellocks - Principles and Function

A rotatable wheel (C) attached to the sqare end of the outer spindle (F) and projecting through the bottom of the flash pan (D) is turned clockwiese (between ½ and ¾ revolution) by use of a cocking spanner (E). This causes the inner chain (G) to be winded around the tumbler or eccenter of the inner spindle, thus lifting one end of the main spring, until a pivot at the end of the primary sear (J) through a hole in the lockplate (K) engages into a recess at the inner side of the wheel and retaining it in spanned position. During this spanning process the sliding pan cover (M) is automaticly opened by the eccenter of the rotating spindle. Now priming powder is filled into the flashpan (D) and the spring-loaded sliding pan cover is closed by pressing the pan cover button (Q). The firearm is now loaded through its muzzle with a powder charge and lead bullet. To fire, the cock (A) is pulled down, whereby the cockspring (N) presses the pyrite towards the surface of the closed pan cover. By pulling the drigger, the released sear lever (O) causes the primary sear (J) to pivot and releasing the wheel. The rotating spindel (F) automatically opens the sliding pan cover. The pyrite (B) is pressed to the outer rim of the rotating wheel by the spring-loaded cock, causing the rotating wheel (C) to strike a shower of sparks out of the pyrite. This will ignite the priming powder and through the touch hole the main powder charge of the firearm. A rotatable wheel (C) attached to the sqare end of the outer spindle (F) and projecting through the bottom of the flash pan (D) is turned clockwiese (between ½ and ¾ revolution) by use of a cocking spanner (E). This causes the inner chain (G) to be winded around the tumbler or eccenter of the inner spindle, thus lifting one end of the main spring, until a pivot at the end of the primary sear (J) through a hole in the lockplate (K) engages into a recess at the inner side of the wheel and retaining it in spanned position. During this spanning process the sliding pan cover (M) is automaticly opened by the eccenter of the rotating spindle. Now priming powder is filled into the flashpan (D) and the spring-loaded sliding pan cover is closed by pressing the pan cover button (Q). The firearm is now loaded through its muzzle with a powder charge and lead bullet. To fire, the cock (A) is pulled down, whereby the cockspring (N) presses the pyrite towards the surface of the closed pan cover. By pulling the drigger, the released sear lever (O) causes the primary sear (J) to pivot and releasing the wheel. The rotating spindel (F) automatically opens the sliding pan cover. The pyrite (B) is pressed to the outer rim of the rotating wheel by the spring-loaded cock, causing the rotating wheel (C) to strike a shower of sparks out of the pyrite. This will ignite the priming powder and through the touch hole the main powder charge of the firearm.

Legend:

A Cock

B Pyrite (iron sulfide)

C Wheel

D Flash Pan

E Cocking Spanner

F Spindle (with sqare end)

G Chain

H Main Spring

J Primary Sear

K Lockplate |

L Recess

M Sliding pan cover

(Spring loaded sliding pan cover)

N Cock spring

O Sear lever

P Bridle

Q Pan cover button (pin)

R Pan cover spring

S Wheel guide (support, retainer)

T Cock bridle (cock brace)

|

Rules and Priciples around wheellock functionality:

- The ignition wheel (C) allways (seen from the front of the lockplate) is winded up clockwise (max. ½ to ¾ of a revolution) and always rotates counter-clockweise when released.

- When supported by a spring-load mechanism, the sliding pan cover (M) will always close (not open), when releasd by the pan cover button (Q). This was already incorrectly descriped by W. Boheim in 1890 and from there went into many publications. Simple wheellock weapons don't have spring loaded pan sliding covers and need to be closed manually.

- The piece of iron pyrite (iron sulfide), which is screwed in between the jaws of the cock, always will be pulled down and dropped on top of the closed sliding pan cover (M), never directly to the outer rim surface of the wheel. This fact is neglected in almost every operating despription for wheellocks. The eccenter of the rotading spindle automatically breaks open the sliding pan cover when the drigger is pulled. Pulling down the pyrite directly on top of the outer rim surface of the wheel would not make any sense, as by motion of the horse all priming powder would be spilled out of the flash pan.

- Differently to the flintlock, where a flintstone is striking sparks out of a carbon steel battery, with wheellocks the sparks will be grinded out of a relatively soft iron pyrite by the rotating ignition wheel (similar to a cigarette lighter). This sparks implement higher temperatures than the first method, the ignition process however is significantly slower and more sensitive to failfunctions. The failure rate, even with perfect adjusted wheellocks is between 10% and 15%. - with poor quality weapons and under battle conditions up to 25%.

|

|